SENTINEL™

Advanced decontamination and chemical filtration

Product Platforms

SENTINEL™

Advanced decontamination and chemical filtration

SENTINEL™ filtration technology enables next-level chemical protection to those who need it most

First responders entrust their lives to advanced personal protective equipment (PPE), keeping them safe from chemical threats while cleaning up industrial accidents, responding to medical emergencies, or managing our rapidly changing environment. SENTINEL™ filtration technology unlocks a step change in filter performance and protection.

Current Use Cases

Chemical Protection

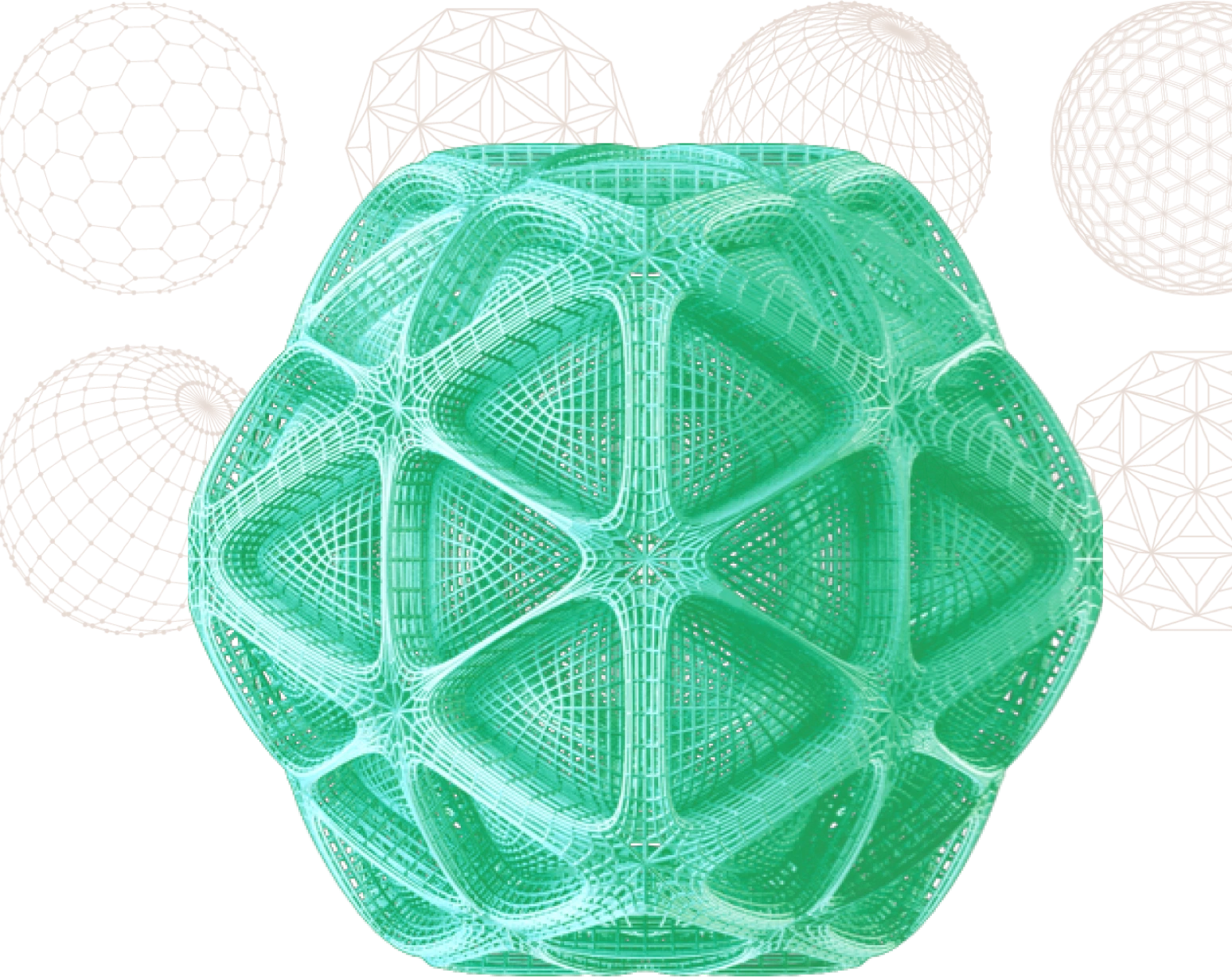

MOFs offer ultra-high porosity and vast surface area capable of effectively removing contaminants in a wide range of technologies, and enable filters that protect better, encumber less and simplify usage

Traditional methods of filtration involve the use of activated carbon to remove impurities. When working in conjunction with carbon, MOF precision chemistries offer a step change in overall filter performance.

Numat’s MOF-based commercial solution, SENTINEL™, is a major step forward; offering protective equipment manufacturers the ultimate chemical protection and detoxification performance.

Decontamination

Complete protection in a single, less hot material

SENTINEL™ materials integrated in existing CWA protection provide high-performing CWA decontamination with the added benefit of reduced thermal burden.

Protective garments without compromise

CBRN garments are notoriously hot and bulky, loaded with toxic PFAS, and difficult to decontaminate. The US Department of Defense has demonstrated that SENTINEL™ is the only material that both captures and destroys chemical warfare agents. When used by garment manufacturers, SENTINEL™ filtration creates low-burden PFAS-free garments that destroy agents on contact.

Decontamination Features

- Decontamination – Captures and destroys chemical warfare agents

- Non-toxic (oral, dermal, inhalation)

- Resistant to humid aging

- Low flammability

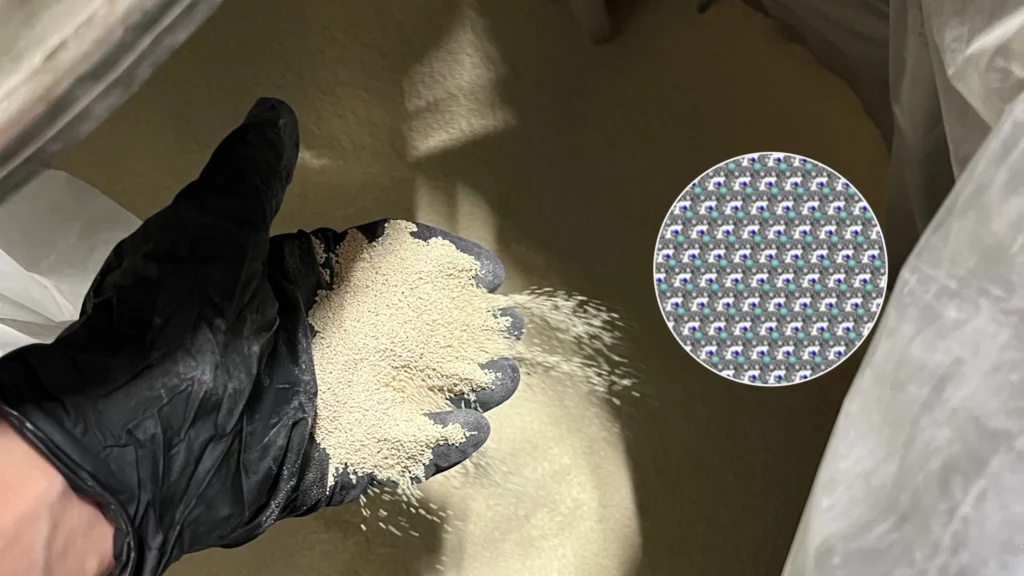

- Drop-in replacement for carbon or zeolite granules

- Supports new chemical functionalities

Filtration

Providing the world’s best respiratory protection to those who need it most

As new threats emerge from unknown toxic agents, new tools are necessary for the warfighter.

Often the first on the ground after a release of toxic chemicals, members of the military require state-of-the-art technology that will filter out toxins and aid with cleanup after an event. Existing chemical protection equipment has known vulnerabilities, leaving our soldiers and first responders at risk. SENTINEL™ filtration fills the gaps, immediately improving threat readiness and unencumbering the warfighter.

Higher performing filter material enables unprecedented design flexibility for filters of all shapes and sizes. Filters developed with SENTINEL™ materials maintain protection while being made thinner, and reducing pressure drop, bulkiness, breathing resistance, and compressor energy cost.

Filtration Features

- 5-20x TIC protection vs. best available alternatives

- Non-toxic (oral, dermal, inhalation)

- Resistant to humid aging

- Low flammability

- Drop-in replacement for carbon or zeolite granules

- Supports new chemical functionalities

Looking Forward

Cleaning the air we breathe

Numat’s SENTINEL™ filtration shields our built environment from industrial emissions by precisely capturing and separating hard-to-abate toxic and greenhouse gasses.

Whether in our homes, offices, or vehicles, we are all exposed to an ever-increasing concentration of toxic chemicals in our air, water, and food. The same technology that protects the lives of our first responders can be used to clean our built environment.

Installed at an industrial or agricultural site, SENTINEL™ filtration will head off pollution at its source. Installed in our buildings, SENTINEL™ filtration provides a defensive barrier against the harmful pollutants that surround us.

Our PLATFORM

Speed Meets Scale

Our world-class platform integrates MOFs into products and processes, merging chemistry innovation with manufacturing at industrial scale.