Process

Our Process

Scaling metal-organic frameworks requires

significant expertise beyond initial chemistry design.

At Numat, we leverage our fully integrated platform combining physics-based modeling, proven engineering and real world application testing to achieve high-volume manufacturing of MOFs. Our platform is designed to reproducibly deliver industrially-validated solutions into the most demanding industries, where performance, compliance and safety are non-negotiable.

Design

Computationally-guided design

01

Discovery

Using proprietary algorithms, we computationally predict the structure of a material solely from the chemicals used in its creation. Through distributed supercomputing, we build massive databases of novel structures for future use – a near limitless chemistry toolbox for the challenges of tomorrow.

02

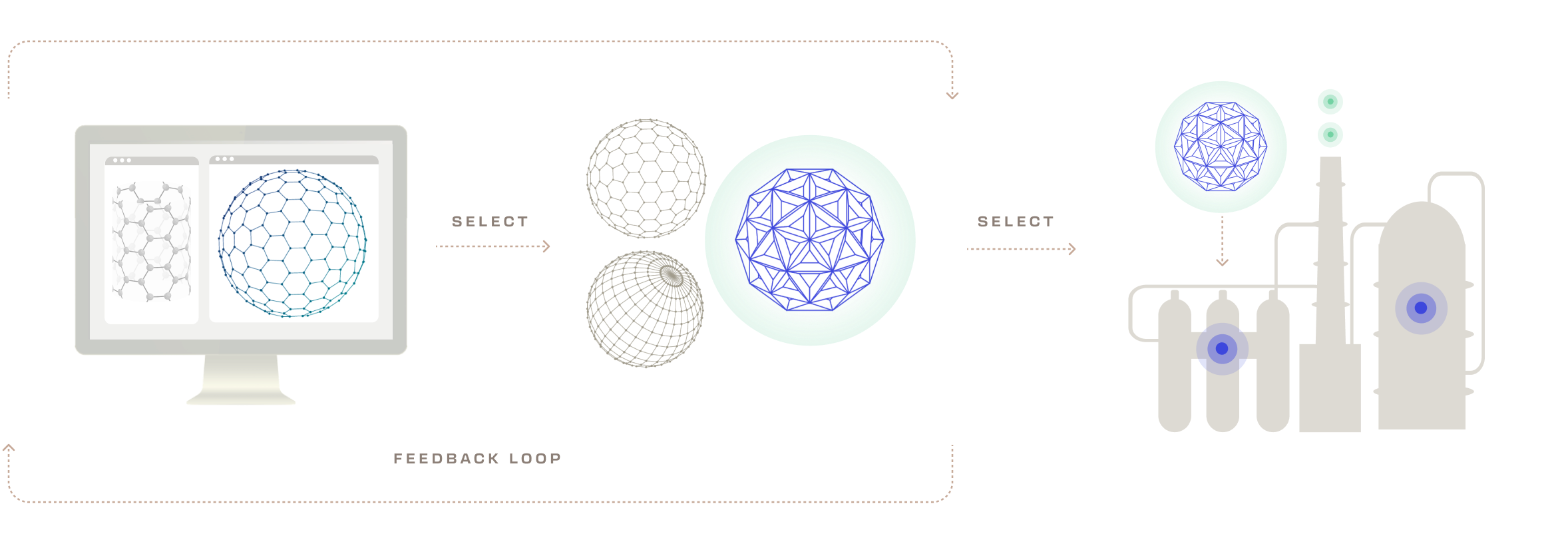

Selection

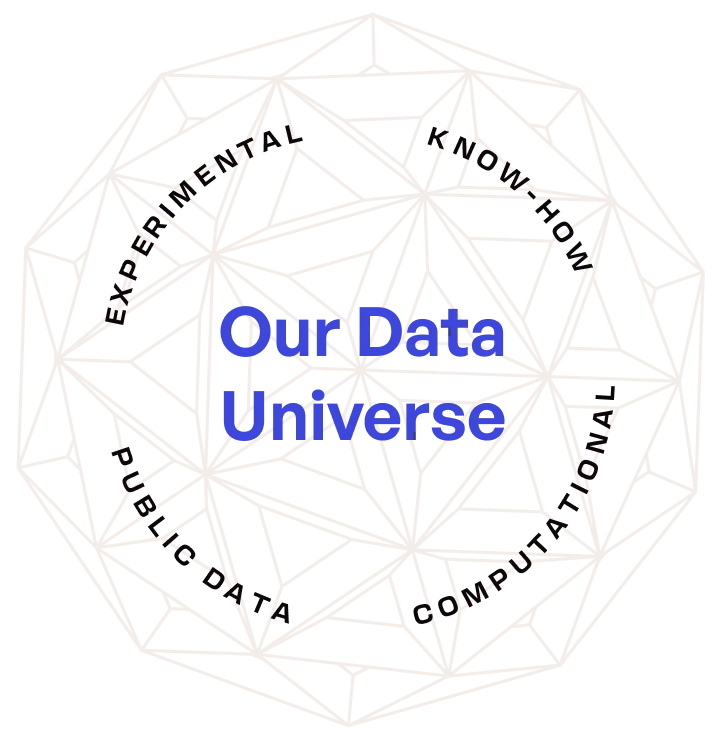

We’ve developed an integrated molecular modeling toolkit, from quantum chemistry through classical mechanics and process modeling; all leveraging state of the art software (both proprietary and open source). This work-flow drives critical insights which enable intelligent material selection and optimization across every step of the discovery process. We also leverage Numat’s Data Universe – including experimental, know-how and available public data to intelligently inform design decisions.

03

The Possibilities of Machine Learning

Looking forward, leveraging our in-house database of 100K MOFs, the possibility exists in our toolkit to integrate structure descriptors and physics-based predictions with targeted lab measurements to build application-specific models that can predict the efficiency of materials from their innate structure and organization.

Test

Application development:

Transforming chemistries into solutions

01

AUTOMATION

Similar to a smart home, we’ve built a “smart lab” where experiments can be run, data collected and decisions made with minimal human intervention. Using open source tools, we’ve established an automation infrastructure where every piece of equipment, whether it be for material characterization or batch chemical synthesis, talks to each other in a unified format. This enables a seamless, and highly automated transition between R&D and manufacturing.

02

ANALYTICS

Through our platform we collect massive troves of data across every step of the development cycle which provides advanced analytical services to our research organization. Whether it be translating complex data sets into mathematical models or visualization maps, our analytics platform provides researchers the real-time insights needed to drive outcomes.

03

APPLICATION DEVELOPMENT

Beyond material discovery and scale-up, significant complexity exists in translating precision chemistries into fully engineered solutions. We do so in dedicated application labs, leveraging our automation and analytics platforms. Whether it be the development of chemical delivery systems for the semiconductor industry or next generation chemical & biological PPE, we design, prototype and qualify engineered solutions, this integrated approach to application development enables a rapid feedback loop where chemistries can be tweaked to optimize system-level performance.

Make

Integrated process scale-up:

From the lab to the plant

01

Process Scale-up

From gram to metric tons, our scale-up work-flow ensures success in the lab translates into solutions in the field. All process engineering is done in a state-of-the-art pilot lab dedicated exclusively to MOFs. Our material formation applications lab ensures synthesized chemistries are transformed into consumable products. This integrated capability system – from discovery through scale-up, accelerates development cycles and de-risks transition into commercial-scale operations.

02

High Volume Manufacturing

Our team has experience producing multiple MOFs at industrial scale for nearly a decade, with a proven ability to execute in 10,000 liter reactors and up. Our integrated process-scale up model enables us to build robust processes that utilize standard fine chemical production equipment. Using both owned assets and a distributed production network model, we’ve proven our ability to successfully execute technology transfer and scale jumps to build a supply chain that is redundant and flexible by design.

03

Finished Goods Assembly

We operate the world’s first and only facility with an ISO 9001:2015 certified quality management system with TUV Rheinland of North America for the final assembly of products integrating MOFs. Our digitized manufacturing management system integrates automated process tracking with batch-level data and global asset tracking, providing full supply chain traceability from raw material to end product.

04

Quality & Compliance

We are committed to providing our customers with the highest quality products and services. We have a rigorous quality assurance program that ensures that our products meet all applicable standards – and a collaborative team culture that aims to exceed them. Numat Technologies, Inc. is ISO9001:2015 Certified with TUV Rheinland of North America.

Our operations lead with safety and compliance first and we comply with all applicable laws and regulations.

We are committed to monitoring our supply chain to assure that minerals are responsibly sourced in accordance with the EICC- GeSI Conflict-Free Sourcing Initiative.

We expect our suppliers to not engage in the use of forced, bonded (including debt bondage) or indentured labor, involuntary prison labor, slavery, or trafficking of persons. This includes transporting, harboring, recruiting, transferring, or receiving vulnerable persons by means of threat, force, coercion, abduction, or fraud for the purpose of exploitation. [US Federal Acquisition Regulation 52.222-50]